Today, a very popular kind of needlework becomes weaving from newspaper tubes. The elements of weaving in this kind of needlework are a bit, the main thing is to perform them correctly. Spectacular completion of the product is a very important part of the work. How to make the bending "Rogging" from newspaper structures: Introducing a step-by-step master class.

Peculiarities

The bending "Rogging" from newspaper pipes At first glance seems difficult to perform an element, but thanks to the beautiful vesible pattern and the accuracy of the edge of the product enjoys well-deserved popularity among the needlewomen.

The design of the product by the bending "Roga" looks neatly and elegant.

Different way to complete bending allows you to give products a beautiful appearance. With the help of "Roga" you can make air baskets, vases, parlor entries, which have a patterned edge in the framework of the bend with the links. Making a bending without units, you can get a product with a dense and smooth edge.

Tools and materials

To perform the bending "Rogging" you will need:

- tubes from newspapers;

- water;

- spray;

- spoke;

- PVA glue.

Step-by-step weaving

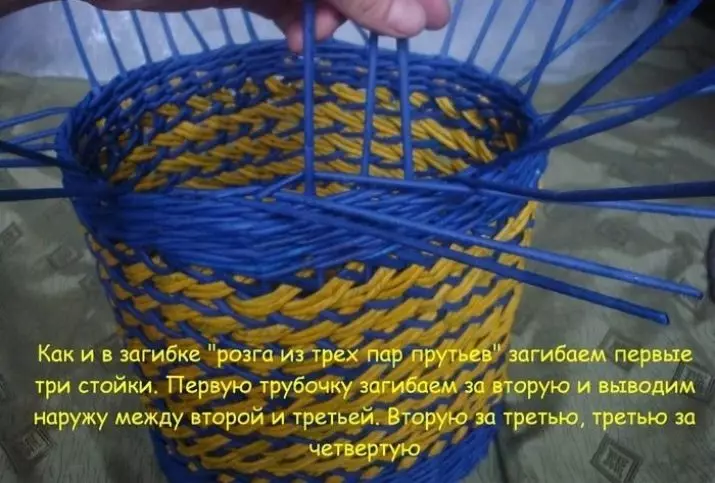

A step-by-step master class will help to understand the basic principle of weaving the bending "Rogging", so that you can finish products from newspaper twists with original weaving without penets from cut racks.

- Websive the volume of the product is needed to the desired height, leaving the racks are long enough. The length of the rack will form a good pattern on the bending.

- After completing the weaving of the main volume of the product, we extract the form of the base out of it. An important detail - before performing the bending well, moisturize the racks. Working with wet tubes is easier, they are elastic and easily succumbed to weaving.

- Under the first rack, we put an extra tube and bend the rack for the neighboring. Similarly, bend the second and third. In order to easily and smoothly bend the elements, you can use the needle. The substitched knitting needles helps slide on weaving.

- Next, you need to return to the first rack and gently beaten it for the fifth. Tube number four also refuel number five for the tube.

- Next, we consistently perform the bend of the second and the fifth rack per tube number six.

- Now we have a pipe number three and six, they need to be filmed in turn for the seventh rack. When performing such actions, three pairs of tubes were obtained.

- The following tubes remaining on the right side bend on the same principle: the free tube bend under the adjacent bottom, then we will turn over the next rack.

- So we work until the pair of newspaper tubes remain. With properly made manipulations, all other racks will be bent three pieces. Now you can perform the formation of links of the pattern of the bending "Rogging". Here again will need an additional twist from the newspaper. We add it to the first rack and bend it in extreme. According to this principle, we form the entire row, turning the pipe bend earlier. The last tube of the row stretch instead of an extra tube, gently pulling it out of weaving.

- The next row bending in the same sequence, with the difference in the direction of the binding. Each next row in the formation of the links woves in the opposite direction. You can stop "Ruga" while the remaining length of the tubes allows. The more rows, the more comprehensive product.

- After completing the weaving the bends, the remaining tips of the newspaper twists remain. Each rack neatly welt the PVA glue, grounding surface. When the glue dries, the remaining tips of the tubes are smoothly cut.

There is another option to complete the bending "Roga". It is used if the edge of the product does not need an additional pattern and thickness.

After completing the weaving of the product itself, begin to perform the bending. Add an additional twist, bend the first rack for adjacent. The same actions are done with the following three racks.

After that, the first and fifth refill in turn for the rack number six. Then - the second and sixth of the seventh, third and seventh for the eighth. The principle of bending bending remains the same as in the previous description.

The remaining pair of racks bend as follows. First we will start for the second, and refuel instead of an additional twist. The remaining rack is gently bended in the first loops of a number of bends and derive the remaining end of the product. Figure completed.

The edges of the tubes are ground with glue, cut and glued to the main flexion from the inside.

Recommendations

There are several key points in the execution of such completion of the wicker product.

- To facilitate the work and accuracy of the performance, it is important to moisten the newspaper twists before the bends. It is better to spray water from the sprayer, so the product will be moistened evenly, and you will have the opportunity at any time sprinkle it again to increase elasticity. But it is not necessary to get involved - excessive moisture deform the material.

- Stretching the tube is better than a metal needle, comfortable length and thickness.

- It should be remembered about the sufficient length of the tubes. Length allows you to form a beautiful, smooth pattern. The more the length of the links at the end of the pattern, the more an openwork will be the edge of the product.

- Do not strongly delay weaving. The drying product may be deformed in this case.

Further, see the master class on the bending "Rogging" from newspaper tubes.