Overlock is a device from the discharge of a sewing equipment, which allows smoothly cutting and process the edge of the product from the fabric. Submitted settings and repair of this device forces to perform only a qualified wizard, but correctly select and debug the tension of the threads before starting work, quite by the usual user.

Fundamental rules

The principle of regulation does not depend on whether Taiwanese, Japanese or Chinese have Overlock, since the tension regulators of the threads are made on the outdoor side of the machine body. As a rule, their 4, according to the number of threads involved in the process of rapidization. All regulators have a scale of tension degree from 0 to 9.

For each type of fabric, before starting work, you need to adjust overlock.

The values of the regulators are set depending on the thickness of the tissue and the type of thread used. In most cases, the exchange can be performed with the value of the tension under the digit "4".

But you should not immediately start processing the product itself. Pre-check the quality of the sputter on the flap of the fabric and, if the process passed normally, you can start working.

The degree of tension of the thread is regulated as follows:

- from 2 to 3 - weak tension;

- from 3 to 5 - average tension force;

- from 5 to 7 - Strong tension.

An important condition for high-quality material bulk is the thread thickness, and it is important that all 4 threads are one species and thickness. Another condition for obtaining a smooth spray line will be the right selection of the needle thickness, the corresponding density of the treated fabric. Usually for each overlock in the instruction manual, the manufacturer indicates the needle brand and their recommended numbers.

If the needle is selected inappropriate size and thickness, it can lead to a failure of the grid process, and in some cases even to the vehicle breakdown.

Tension thread

Each tension regulator performs its function, on overlock they are painted in a certain color. The function is as follows:

- First regulator - responsible for tensioning the filament of the machine's left needle;

- Second regulator - responsible for tensioning the thread of the right needle;

- Third regulator - pulls the thread of the upper looper;

- fourth regulator - pulls the thread of the lower looper.

When tuning, use a piece of tank as a prototype and carefully examines the quality of the line. Inspection and necessary adjustment in the following sequence.

- Check the work of the left needle. If we see the fabrics, it means that the thread tension force is too large. Therefore, we reduce the indicator of the regulator to one division and again check on the tissue sample, how the line will look like. The tension is tensioning until the wrinkles on the processed cut will not disappear.

- Check the accuracy of the stitch. For this also answers the left needle. If you see the "ladder" from the thread, then the tension must be slightly increased.

- As soon as they found the desired indicator for the left needle, in which a smooth line is obtained without wrinkling the tissue and weakening the threads, then we are exposing the same for the right needle of overlock.

- We estimate the operation of the loopers. The lines on the fabric should be smooth, the drawing between stitches is uniform. If you will see the loops of the threads in the edge of the processed tissue, it means that the tension of the strains of the loopers is too weak - it needs to be increased. The adjustment is performed until the threads for which the loopers respond will not be lying exactly.

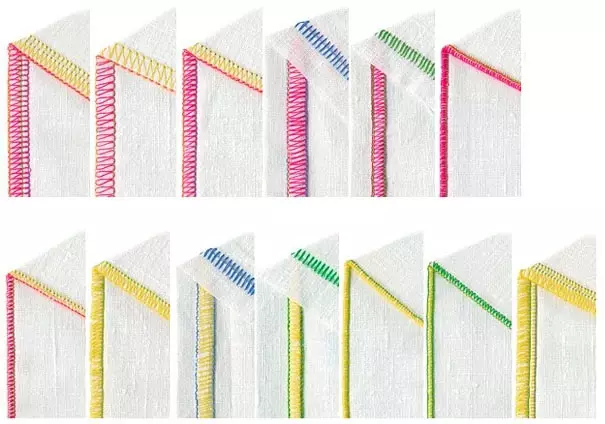

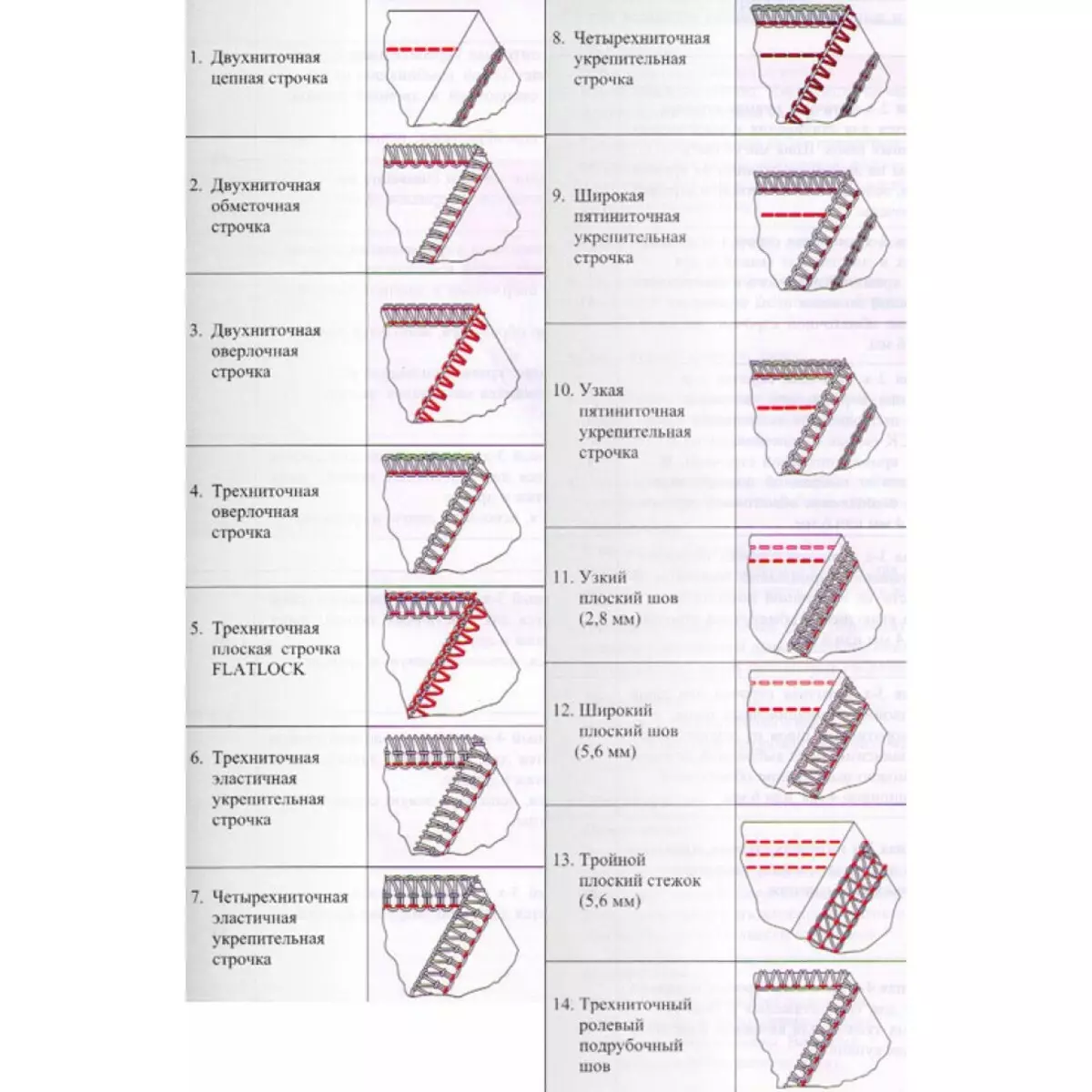

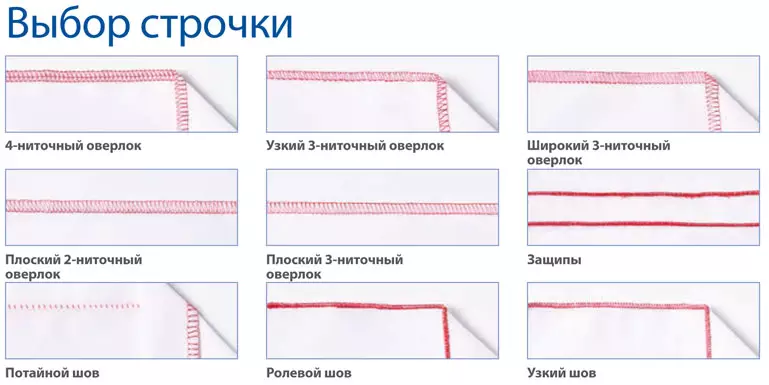

When processing the product, it is important to choose a line type corresponding to the thickness of the tissue. Most modern corrugated machinery can perform at least 5 types of lines.

- Highlighting line of 4 threads. All 4 threads and 2 needles are used in the process. Such a line provides durable seams and can be applied to knitwear and any dense textiles.

- A pitching line of 3 threads with a seam width of 5 mm. Performed with the left needle and 3 threads. Suitable for medium density tissues.

- A pitching line of 3 threads with a seam width 2.8 mm. Performed with the right needle and 3 threads. Applied to a thin fabric.

- Narrow row row 2 mm wide. Used on chiffon and other thin tissues.

- Two mm width bearing stitch. Used as decorative for thin tissues.

Processing thin fabrics, it is important not only to configure the indicators of tension controls of the threads, but also the pressure leg of the machine. If the pressure of the foot is too strong, then no adjustments will help, and the fabric will be shrivened when processing until this reason is eliminated.

Stitch size

To get a flat line when processing the product, except other settings, it is important to choose the correct stitch size. To do this, there is a special regulator with a division scale. The choice of the regulator indicator depends on the tissue density. The thinner the tissue, intended for the mark, the less should be the stitch size. Choosing the length of the stitch, do not forget to take into account the thickness of the thread.

When configuring an overlock, you will help to navigate the following information:

- Thin fabric (George, Batist, Kiese) - stitches 2-3 mm, thread number 80-90;

- Material of medium thickness (subtle cloth, gabardine, serge) - 2.5-3.5 mm stitches, thread number 60-80;

- Tight fabrics (tweed, jeans, knitwear) - Stitch 3-4 mm, thread number 50-60.

In some cases, during operation, you will see that the stitch has a stitch skip. Adjust this process will help you with the following actions:

- Check the needle state - Whether she wondered whether it was installed correctly;

- Remove the needle and check her number - if it does not correspond to the type of your overlock, replace;

- Examine whether your car is filled correctly , is not missed one of the attachments;

- Make sure the threads have not wound on the stitch adjustment pin;

- Rate pressure presser foot.

After checking all the indicators, make an experienced sample and, making sure in the normal operation of the stitching machine, proceed to the processing of the product.

Recommendations

For the normal and long-term service of your overlock, it is necessary to regularly carry out its maintenance. This procedure is as follows.

- Cleaning the mechanism. This simple manipulation is performed each time after the completion of the work. It is necessary to remove dust, trimming fabrics, threads. This can be done with a rigid brush by vulnerable movements.

- Lubrication overlock. To ensure the smooth and silent operation of moving nodes of the mechanism, the machine is required to periodically lubricate with special oil. Lubrication is performed only after pre-made thorough cleaning.

When detecting serious malfunctions, overlock should be repaired in service centers of maintenance of household appliances, and when replacing nodes or parts, it is important to use only original spare parts from proven suppliers.

For more information about setting up Overlock, see the video presented.